In real-world power systems, a single power plant often supplies electricity to a large region—serving homes, schools, hospitals, factories, and more. A wide-area power outage can cause severe inconvenience and significant economic loss. Ensuring the stable and reliable operation of the power system is therefore essential.

In this process, the protection relay plays a crucial role.

A protection relay is an intelligent device used to monitor electrical parameters such as current, voltage, frequency, and phase angle. When it detects abnormal conditions—such as overcurrent, short circuit, or voltage instability—it sends a trip signal to the circuit breaker, isolating the faulted section from the rest of the system.

In a substation, the protection relay functions as the “nervous system” of the grid—detecting faults rapidly, pinpointing their locations accurately, and ensuring system stability and safety.

(1) Overcurrent Relay (OCR)

Function: Detects when current exceeds a preset value, indicating overload or short circuit.

Applications: Transformer protection, feeder protection, motor overload protection.

(2) Earth Fault Relay (EFR)

Function: Detects leakage current caused by insulation breakdown or ground faults.

Applications: Transformer winding protection, cable insulation monitoring.

(3) Distance Relay (Impedance Relay)

Function: Measures the impedance between the relay and the fault location; lower impedance indicates a fault closer to the relay.

Applications: Transmission line protection in high-voltage substations.

(4) Differential Protection Relay

Function: Compares the current entering and leaving an electrical component (e.g., transformer, generator); any difference indicates a fault within the protection zone.

Applications: Transformer differential protection, generator protection, busbar protection.

(5) Directional Overcurrent Relay (DOCR)

Function: Detects overcurrent and determines the fault current’s direction.

Applications: Parallel feeder systems, ring networks.

(6) Overvoltage/Undervoltage Relay

Function: Monitors voltage levels and trips when voltage exceeds or drops below acceptable limits.

Applications: Voltage regulation in substations, generator protection.

(7) Frequency Relay

Function: Detects abnormal frequency deviations, indicating generator load imbalance.

Applications: Generator and grid protection in power plants and substations.

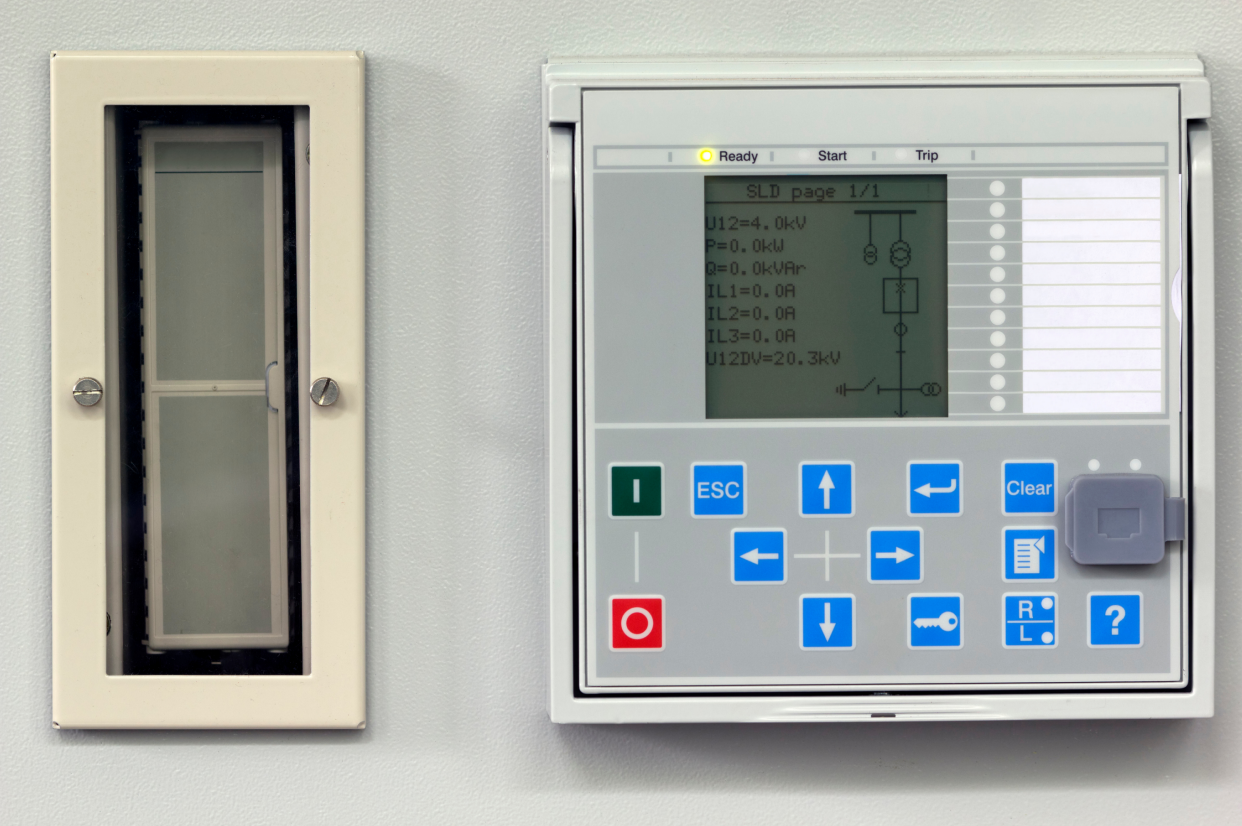

(8) Digital (Microprocessor-Based) Relay

Function: Integrates multiple protection functions in one device, offering advanced settings, self-diagnostics, and communication features.

Applications: Modern intelligent substations, automated power grids.

Before a protection relay or automation device is put into service, it must undergo a series of thorough checks to ensure all functions are intact and capable of executing protection and control tasks accurately and promptly.

Key checks include:

Inspecting the exterior and internal components for damage.

Verifying correct wiring.

Confirming protection settings match specified values.

Ensuring no personnel are present in the circuit during commissioning.

Checking relay enclosures and seals for integrity.

Restoring all secondary circuit connections.

Commissioning/Decommissioning Sequence:

Ensure AC power supply is stable.

Sequentially energize DC power, checking relay contacts, signal lights, and meters for accuracy.

Engage the protection link panel and measure terminal voltages.

For shutdown, follow the reverse sequence.

Routine patrol inspections by on-duty personnel are essential to maintain safe and reliable operation.

During operation, regular inspections are required to confirm normal conditions and address potential abnormalities.

Daily Inspection Items:

Verify status of secondary circuits and link panels.

Check relay cases, contacts, indicator lamps, and signal relays for irregularities.

Ensure switches, isolators, fuses, and connecting plates are correctly positioned and in good contact.

Inspect protective indicator lamps, signal relays, and meters for abnormal readings.

Confirm relay coils, terminals, and wiring insulation are intact.

Functional Testing:

In addition to daily patrols, periodic functional testing is vital. A protection relay tester can simulate various fault conditions in the power system and verify that the relay responds correctly by issuing fault signals and operating as intended.

When an abnormality occurs, follow established procedures to record the relay's operation and, if necessary, remove the device from service. For example:

If the relay itself malfunctions or risks false tripping.

If the AC voltage circuit in a protection device fails.

Such cases require immediate corrective measures and prompt reporting to the responsible supervisor.

Special attention should be given to microprocessor-based protection and automatic transfer devices:

Confirm display and indicators are accurate.

Check for overload, overheating, or unusual odors.

Inspect device panels for alarm signals.

A healthy relay should have no abnormal messages on the LCD, no lit fault LEDs, and a green "in service" indicator illuminated.

Verify link panels are correctly clamped and remote control switches are in the proper position.

The protection relay is the first line of defense in a substation, ensuring the stability, reliability, and safety of the power system. From basic overcurrent relays to advanced digital devices, each type plays a unique role in fault detection and isolation.

As power grids evolve toward intelligent automation, selecting the right protection relay has never been more critical.