LPIT (Low Power Instrument Transformer) is a measurement and protection device used in power systems, designed to convert high voltages and large currents into low-power analog signals for subsequent digital processing and analysis. The application of LPIT technology has made power system monitoring, control, and protection more precise, efficient, and reliable.

LPIT (Low Power Instrument Transformer) is a voltage or current transformation device characterized by an extremely low output power, typically on the order of milliwatts. Compared to traditional electromagnetic instrument transformers, an LPIT provides low-level analog signals at its output. These signals can be directly connected to electronic measurement and protection equipment, enabling high-precision data acquisition and processing.

The working principle of an LPIT is based on electromagnetic induction or optical effects. Using specially designed sensing elements, it converts the primary side’s high voltage or large current in a fixed ratio into a low-power analog signal on the secondary side. To ensure the accuracy and stability of the signal during transmission, the system should meet the EMC immunity requirements of IEC 61869-6 and utilize shielded cables or optical fibers to reduce transmission loss and interference, thereby effectively improving the reliability of the measurement results.

High-accuracy measurement: LPIT can provide highly accurate voltage and current measurements, with an error range far smaller than that of traditional instrument transformers, meeting modern power systems’ requirements for high-precision metering and protection.

Low-power output: Because the output power is extremely low, an LPIT’s self-consumption during operation is minimal. This helps reduce the overall energy consumption of the system, in line with the green energy-saving trend.

Good linearity and wide bandwidth: LPIT maintains a linear output over a broad frequency range, accurately reflecting changes in the primary-side signals. This makes it suitable for various complex power system environments.

Strong electromagnetic interference immunity: With special design and materials, an LPIT has a much stronger ability to suppress electromagnetic interference compared to traditional electromagnetic transformers. It can operate stably in harsh environments involving high voltage and large current.

High safety: The secondary-side output of an LPIT is a low-power signal. Even if a short circuit or open circuit occurs, it will not produce dangerous over-voltages or over-currents, thus ensuring the safety of personnel and equipment.

Smart substations: In smart substations, LPITs are used in conjunction with merging units (MU) to convert analog signals into digital signals. These digital signals are transmitted via fiber-optic Ethernet to protection, control, and metering devices, achieving full-station digitization and information sharing.

High-voltage direct current (HVDC) systems: LPITs can accurately measure DC voltage and current, providing reliable data support for the control and protection of HVDC transmission systems.

Renewable energy generation systems: In wind, solar, and other renewable power generation systems, LPITs are used to measure the voltage and current at generator outputs and grid connection points, enabling real-time monitoring and control of the generation status.

Industrial electrical systems: LPITs are widely used in the electrical systems of large industrial enterprises for energy metering, equipment protection, and power quality monitoring, thereby improving the automation and intelligence level of industrial power management.

The low-power analog signal output by an LPIT needs to be synchronously sampled and digitized by a merging unit (MU), which converts it into a digital signal conforming to the IEC 61850-9-2LE standard. In this way, it can be recognized and utilized by new-generation digital protective relays, control devices, and metering devices.

As the bridge between an LPIT and the secondary equipment, the merging unit undertakes critical tasks such as signal conditioning, sampling synchronization, data packetization, and communication transmission. Its performance directly impacts the measurement accuracy and reliability of the entire system.

As power systems continue to advance toward greater intelligence and digitization, higher performance requirements are being placed on instrument transformers. LPIT technology is also continuously innovating and improving, mainly reflected in the following aspects:

Higher accuracy class: Developing LPITs with higher accuracy classes to meet the stringent metering and protection requirements of ultra-high-voltage, large-capacity power systems.

Integrated design: Integrating LPITs with merging units and protection/control devices into a compact, all-in-one unit to reduce footprint and installation costs.

New sensing materials: Exploring and applying new sensing materials—such as optical crystals and nanomaterials—to further enhance the performance and stability of LPITs.

Intelligent functions: Equipping LPITs with intelligent functions like self-diagnosis and self-calibration to enable real-time status monitoring and fault early-warning, thereby improving the efficiency of device operation and maintenance.

LPIT, as a cutting-edge measurement technology in power systems, provides a solid foundation for the intelligent upgrading of the grid. Its advantages of high accuracy, low power consumption, and strong anti-interference capability give it broad application prospects in smart grids, renewable energy integration, industrial automation, and other fields.

With the continuous maturation and refinement of this technology, LPITs will play an increasingly important role in future power systems, helping to build a safer, more efficient, and greener energy infrastructure, and providing reliable electric power support for social and economic development.

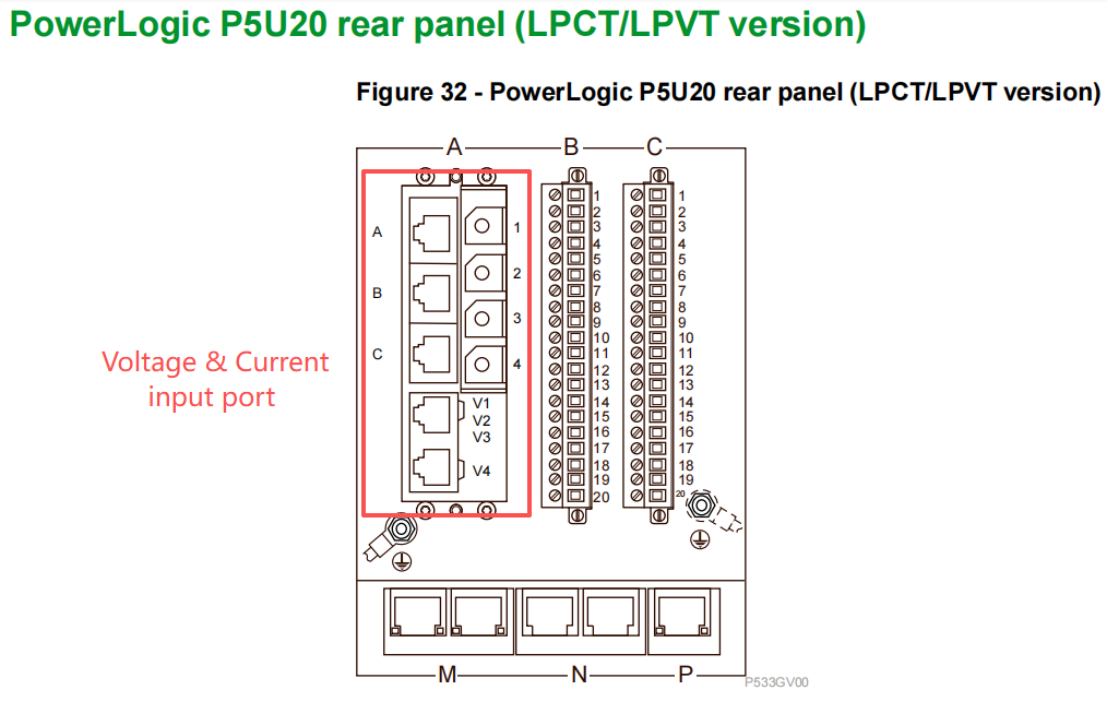

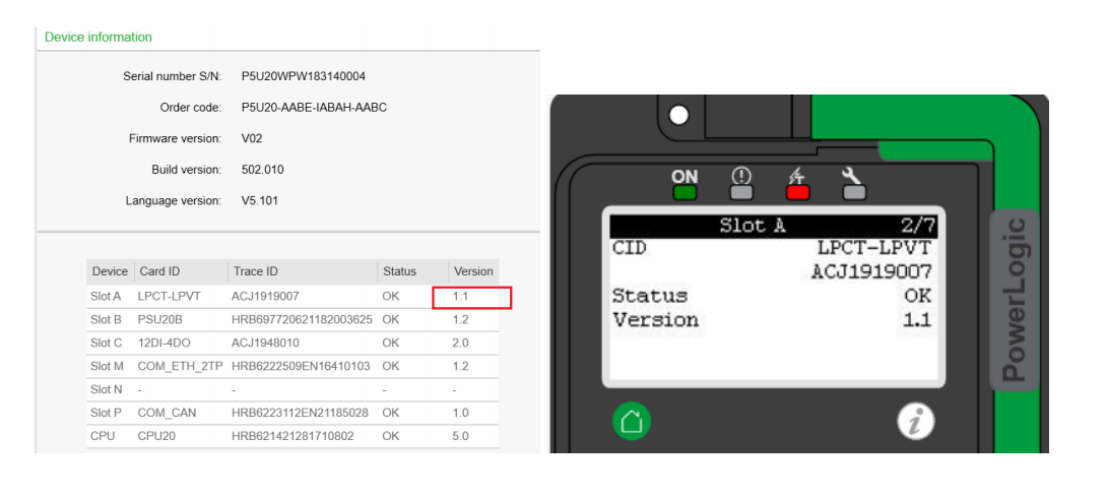

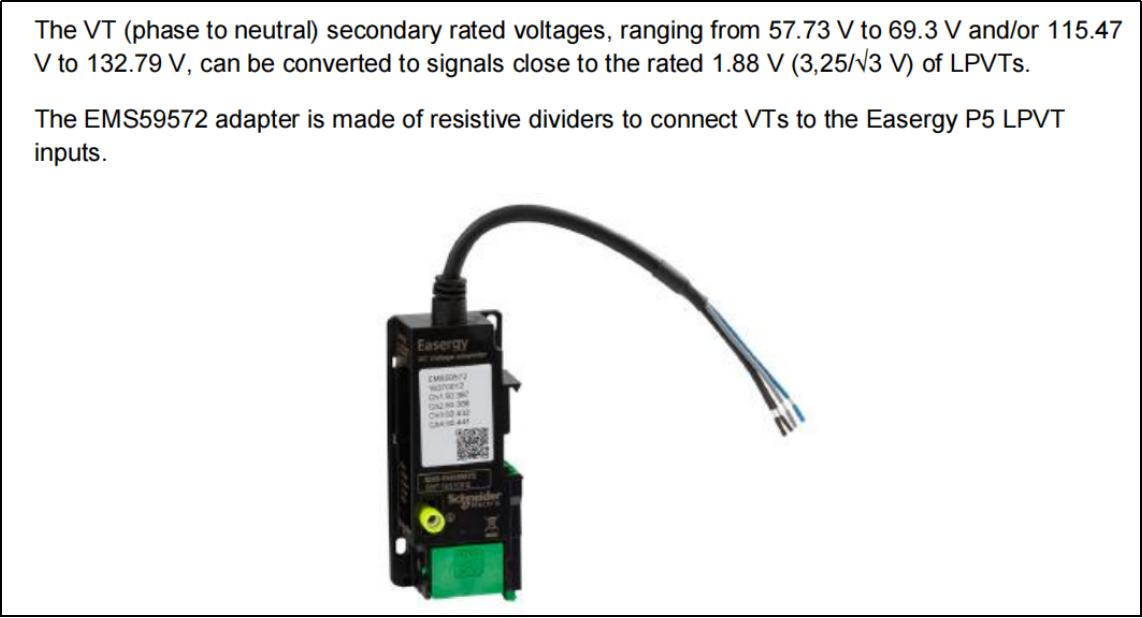

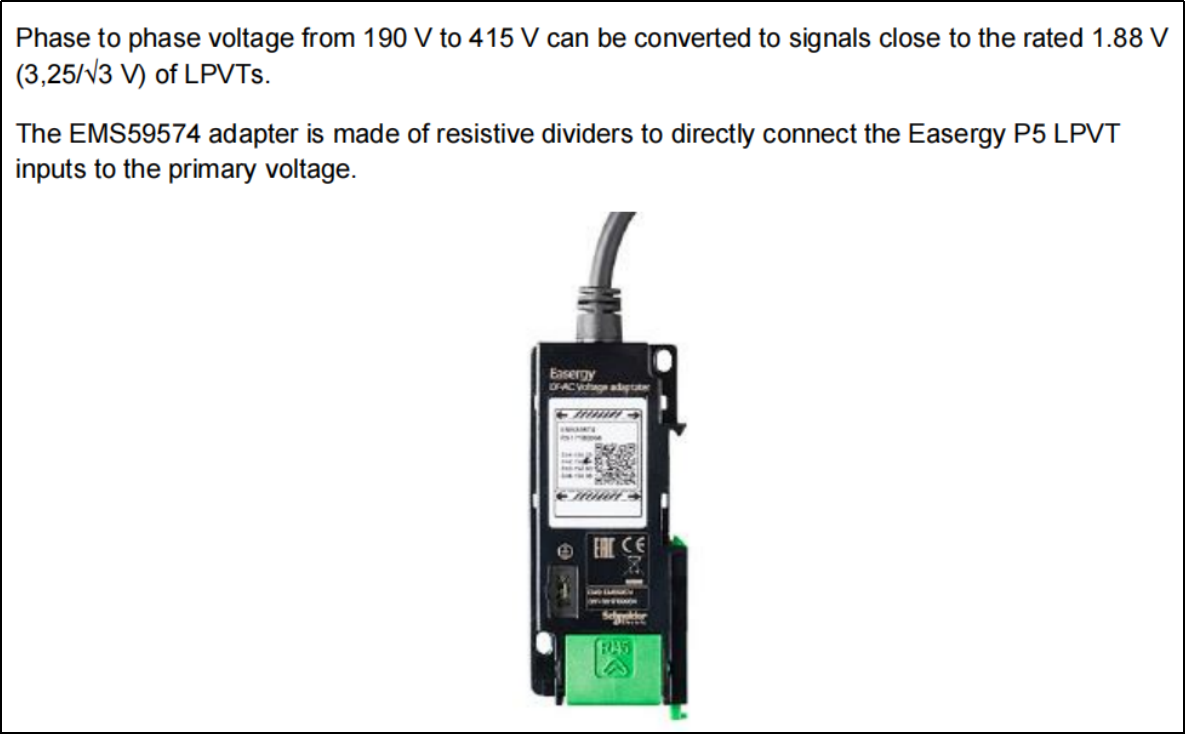

For testing LPIT-based protection devices, the KFA320 relay test set provides a comprehensive testing solution. For example, using a Schneider PowerLogic™ P5 protection and control relay as the test device (its input terminals are shown in the figure below), the procedure is as follows:

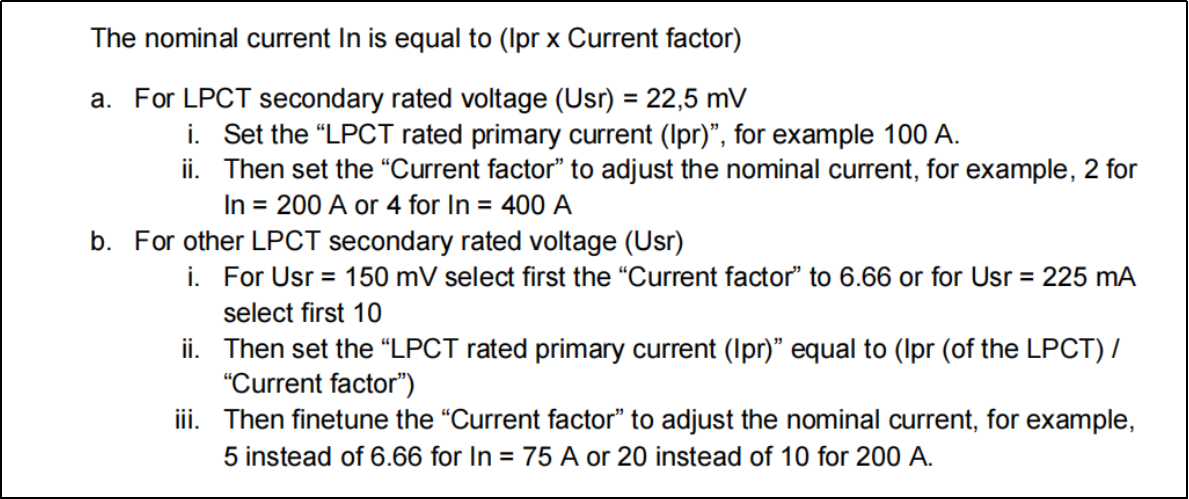

(1) LPIT mode setup: Set the P5 relay’s LPIT operating mode to LPCT+LPVT (Low Power Current Transformer + Low Power Voltage Transformer).

(2) Ratio configuration: Configure the corresponding LPVT and LPCT transformation ratios.

(3) Tester configuration: Set up the KFA320 protection relay test set (the figure below shows the LPIT test box, including a side view of the device).

(4) Connections and software: Connect the KFA320’s OUT1–OUT4 outputs to the relay’s RJ45 voltage/current input interfaces (the software configuration screen is shown in the figure below).

(5) Testing mode: After the software is configured, switch the KFA320 to LLV output mode. The subsequent protective function tests can then be performed in exactly the same way as with a traditional protection device testing mode.