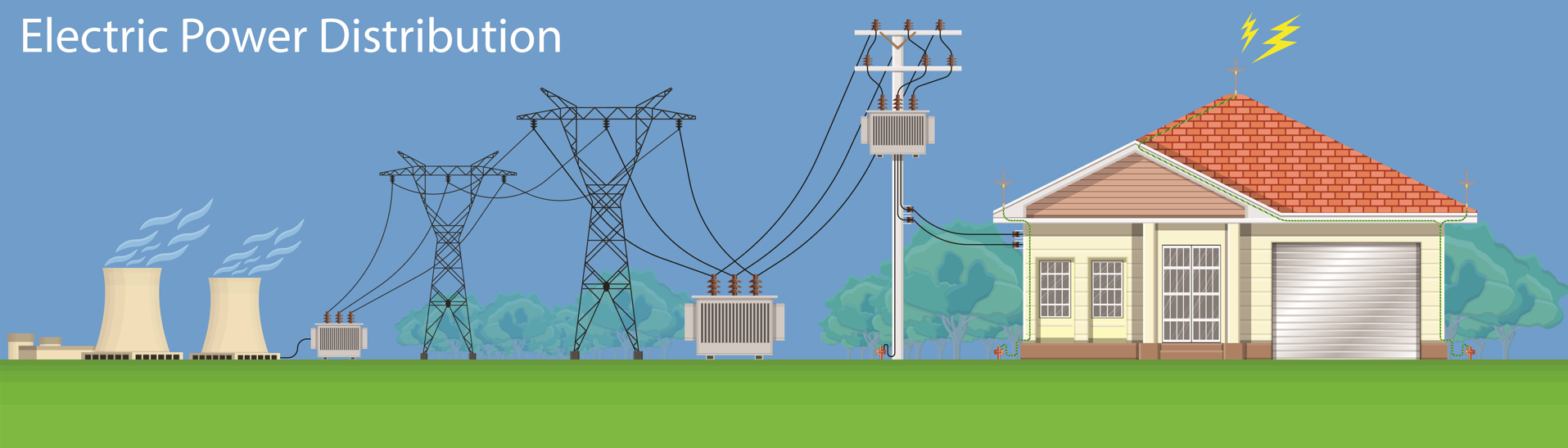

Electric power is an indispensable resource that keeps our modern lives running efficiently and conveniently. The process of delivering electricity—from the moment it is generated to the point it reaches our homes—is highly complex. Substation equipment plays a critical role in this process. By integrating and connecting various substation components, electricity generated at power plants can be transmitted and distributed safely and efficiently to every household.

Substation equipment is generally divided into primary equipment and secondary equipment.

Primary equipment refers to high-voltage electrical apparatus directly involved in generating, transmitting, and distributing electrical energy. This includes generators, transformers, circuit breakers, disconnect switches (isolators), automatic switches, contactors, knife switches, busbars, transmission lines, power cables, reactors, and electric motors. These devices are interconnected to form generation, transmission, and distribution systems—or to support other industrial processes.

Secondary equipment refers to low-voltage electrical devices that monitor, control, regulate, and protect primary equipment. These systems also provide operational data, condition monitoring, and control signals for operators and maintenance personnel. Key secondary equipment includes control panels, measurement and control panels, protection panels (including protective relays and automation devices), low-voltage distribution boards, DC supply panels, batteries, chargers, uninterruptible power supplies (UPS), terminal boxes, interlocking devices, measuring instruments, transducers, fuses, auxiliary switches, secondary cables, and supervisory control systems.

A generator converts various forms of energy into electrical energy through electromagnetic induction. Generators come in many types, ranging from large-scale units in power plants to portable household generators and specialized units for unique applications.

In power plants, the main types include:

Conventional fuel generators (coal, gas, diesel) – Over 60% of global electricity generation, mature technology but higher emissions.

Renewable energy generators (wind, solar PV, hydro) – The fastest-growing segment, reaching 29% of global generation in 2022 (IEA data).

Nuclear generators – Powered by nuclear fission, with approximately 440 operational units worldwide (World Nuclear Association, 2023).

A power transformer is a static device that changes AC voltage (or current) from one level to another while maintaining the same frequency. Transformers are classified into step-up and step-down types.

Electricity generated in power plants typically leaves the generator at 10–30 kV. For efficient long-distance transmission, step-up transformers raise the voltage to 220–800 kV. As the electricity approaches urban areas, a series of step-down transformers reduce the voltage in stages until it reaches standard household supply levels.

Circuit breakers are critical for ensuring safe and continuous operation of the power system. High-voltage circuit breakers, essential in power plants and substations, are equipped with arc-extinguishing capabilities.

Under normal operation, they switch on and off to control load and no-load currents.

In the event of a fault, they work in coordination with protective relays to quickly interrupt fault currents, preventing equipment damage and power outages.

The reliability of high-voltage circuit breakers directly affects the safety of the entire power grid.

Disconnect switches are mechanical devices used to isolate electrical equipment from live circuits for maintenance, transfer operations, or small-load switching. They do not have arc-extinguishing capability.

Main functions:

Safety – Isolating the power source ensures that equipment under maintenance is physically separated from the live grid.

Operational flexibility – In double-busbar systems, they enable smooth transfer of loads or equipment between busbars.

Small-load control – Capable of connecting or disconnecting low-current circuits to facilitate flexible network configurations.

CTs and PTs are essential measuring devices that operate on similar principles to transformers, converting high voltage or current into proportional low values for safe measurement and protection.

Reasons for use:

Safety – Prevents direct measurement of dangerous high voltages or currents.

Accuracy – Provides standard inputs for protective relays, meters, and monitoring systems.

Isolation – Electrically separates personnel and low-voltage control circuits from high-voltage systems.

CTs and PTs are indispensable in transmission, distribution, and control applications for real-time monitoring of phase, voltage, and current.

Secondary systems monitor, measure, control, and protect the operation of primary equipment and the overall power system. These include DC systems, station auxiliary power, supervisory control systems, secondary control loops, microprocessor-based protective relays, measuring devices, and metering systems.

Key examples:

Remote communication and GPS synchronization panels – Contain remote communication units, protocol converters, and GPS clocks to ensure accurate data exchange with dispatch centers and time synchronization across devices.

General measurement and control panels – Measure DC systems and bus voltages (commonly used in ≤35 kV substations).

Low-frequency/low-voltage load-shedding panels – Automatically shed loads when bus voltage or frequency drops below thresholds.

Relay protection test power panels – Provide controlled DC power for testing protective relays.

Main transformer protection/control panels – Incorporate differential, backup, and non-electrical protection for transformers.

Feeder protection/control panels – Monitor feeder circuits and trip in case of faults to protect personnel, equipment, and the grid.

Energy metering panels – Record power consumption data for each feeder.

DC charging panels – Convert AC station supply into DC for use by protection and control equipment, while monitoring each DC feeder’s status.

Used to verify the operational reliability of protective relays in substations. Relay protection is vital to safeguard the entire power system by isolating faults rapidly and accurately.

KINGSINE's testers simulate common fault conditions and send test signals to relays to confirm correct performance. Built with an integrated battery and Linux-based professional test software, our units require no external power supply or computer. This compact, breakthrough design weighs only 3.8 kg—making it the lightest in its class.

Designed for comprehensive analysis of current transformers and potential transformers. Similar to our relay testers, the KINGSINE CT/PT analyzer is engineered for portability with a mini-size design, weight under 8 kg, built-in touchscreen, and pre-installed test software.

Essential for utilities and industrial users to verify AC system parameters such as phase, current, and voltage. KINGSINE’s Power Source & Calibrator delivers AC/DC voltage and current with 0.05% accuracy, ensuring precise calibration. All our products come with a three-year free warranty and lifetime maintenance service.